10 Simple Techniques For Motorcycle Parts New Zealand Specialists

Wiki Article

The 30-Second Trick For Motorcycle Parts New Zealand Specialists

Table of ContentsThe 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsSome Known Details About Motorcycle Parts New Zealand Specialists Little Known Questions About Motorcycle Parts New Zealand Specialists.Motorcycle Parts New Zealand Specialists for BeginnersThe Motorcycle Parts New Zealand Specialists StatementsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.An Unbiased View of Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand Specialists

Reach out to one of our professionals today.CNC machining innovation is swiftly becoming the prime focus of various manufacturing procedures around the world as a straight outcome of its many advantages over various other techniques. Furthermore, the sectors that make motorbikes have obtained on board with this pattern. One of the most cutting-edge companies are currently developing their engine elements and wheels utilizing machining techniques initially created for motorbike parts.

On the various other hand, the effects of sector are the primary focus of this write-up. Let's get directly into it. You may be wondering why we make use of. It is not difficult to fathom the variables that resulted in this result. Since we have your focus let us describe the rationale behind this modern-day growth in the motorbike manufacturing market.

Some Ideas on Motorcycle Parts New Zealand Specialists You Should Know

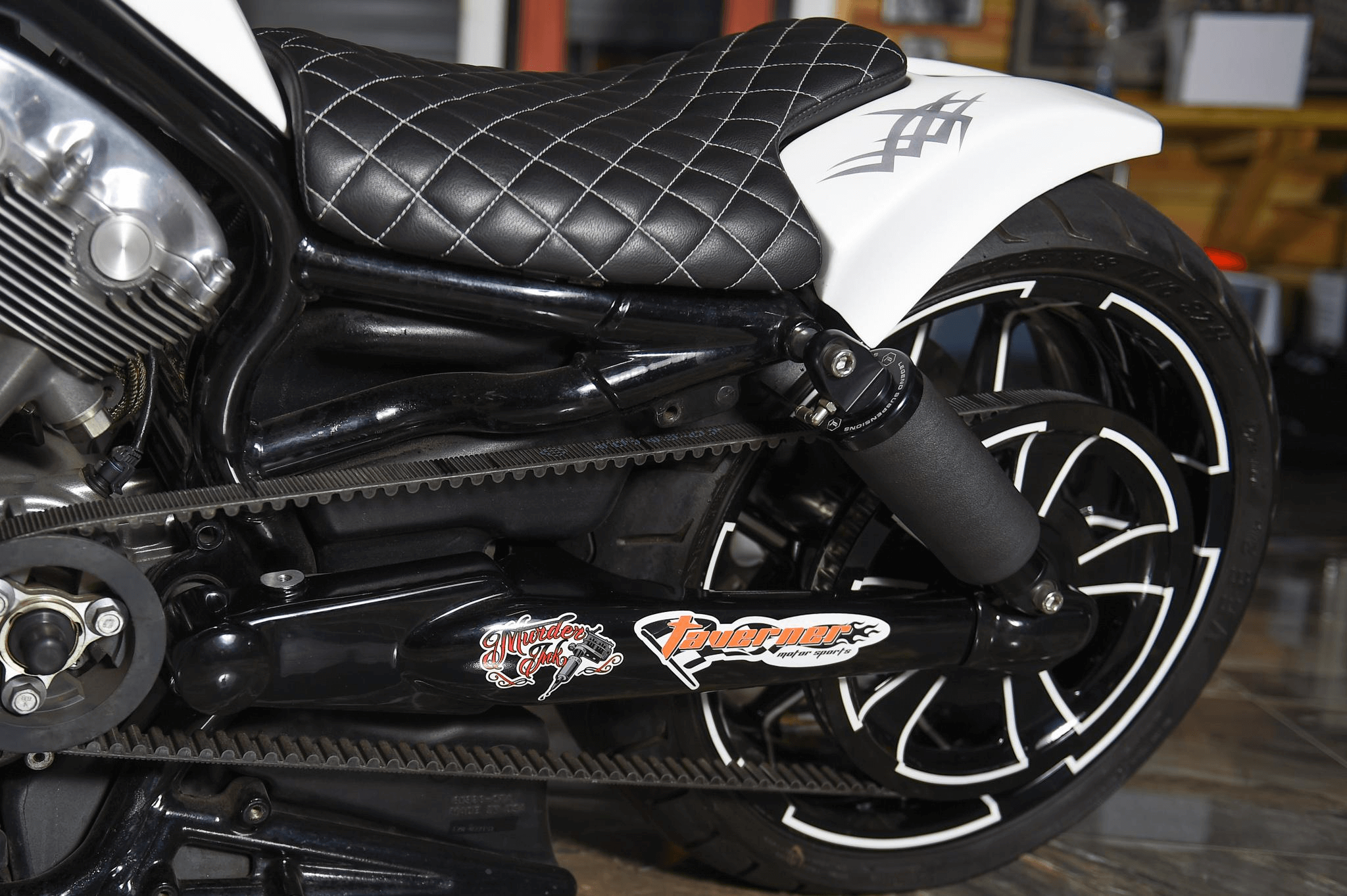

Additionally, you have full control over the appearance of the components, even to the min details. Sometimes, motorcyclists might decide to improve their experience by mounting aftermarket parts or customizing the bike's remodeling. As soon as once more, computer system mathematical control (CNC) machining is the most useful approach. Upgrades may be of any kind of type and style you want.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered

CNC machining might be used to make almost all of a motorbike's steel and plastic parts. To continue, we'll talk about a number of machined parts for motorbikes.When tailoring the wheels, the disks are where the emphasis must be. The majority of them are made out of aluminum. Aluminum alloys are widely known for the impressive machining capabilities that they have. Milling treatments are used to acquire the preferred level of wheel customization. An additional element of the bike that may be personalized is the tires.

The 6-Second Trick For Motorcycle Parts New Zealand Specialists

When it concerns an automobile (or a motorcycle), the most vital element is the engine. Numerous people point to it as the "heart" of the car. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and require layouts with a high degree of accuracy.Usage just high-quality products, nonetheless, considering that these lights are important for the security of motorcyclists and various other vehicle drivers or individuals on the roadway, particularly at evening. Motorbike headlights have 3 major parts: the bulb, or light source, the lens, and the real estate.

Milling processes with a flawless surface would certainly cause the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not made up of breakable materials; instead, it is constructed out of difficult polymers that can be machined right into even more complex patterns.

Excitement About Motorcycle Parts New Zealand Specialists

They typically have sophisticated geometries with a wide range of minute information. Motorbike suppliers frequently cast these elements, however only for the manufacturing of bespoke components. Nonetheless, CNC machining is the approach of option when producing special pieces. Machining on 5 axes in today's globe is the means through which any type of style shape may be understood.Choose Runsom for your tailored motorcycle parts! We have the ability to make challenging and stylish components making your motorcycle unparalleled.

Right here are a couple of examples of steels often utilized in motorcycle element machining. Light weight aluminum is the main product made use of by business specializing in producing customized motorbike parts to create many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more metal that is really light in weight and has fantastic machining qualities because of its high mechanical toughness. This material may useful link be created into almost any shape and maintains its measurements well. Even mission-critical parts that need a high degree of accuracy may benefit from their usage.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

An additional metal that sees heavy usage in the production of CNC-customized elements is magnesium. It is among the lightest steels that are now available and has superb machinability attributes and strength appropriate with its reduced weight. Among the disadvantages of magnesium is that its dirt might easily ignite.

Due to the fact that of its superior machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC processes. They have great corrosion resistance and a high visual appeal. Their most common use in creating different motorbike elements is fasteners, such as screws and screws. Their reduced vulnerability to oxidation and corrosion makes them excellent for this use.

The 5-Second Trick For Motorcycle Parts New Zealand Specialists

It appears that CNC turning and crushing are the foundational procedures. Different strategies exist, such as drilling. Allow's check view website out most of these machining methods comprehensive. The CNC transforming technique is taken into consideration a subtractive production approach. Furthermore, it calls for maintaining bars of material, usually plastic or metal, in placement and after that turning a cutting device to remove sections of the material as the product is transformed.

These approaches are equally crucial and generate elements with high accuracy and consistent top quality. The procedures aid improve the total high quality of the machined motorbike components.

The Facts About Motorcycle Parts New Zealand Specialists Revealed

Report this wiki page